Top 10 Best 55 Gallon Drum Transfer Pumps for Efficient Fluid Transfer

When it comes to the efficient transfer of fluids, selecting the right equipment is crucial, especially in industrial and agricultural settings. Among the various tools available, the 55 gallon drum transfer pump stands out as an essential device for moving liquids from large drums with ease and precision. Whether you're dealing with oils, chemicals, or other viscous substances, having a reliable pump can significantly streamline operations and enhance safety.

In this guide, we will explore the top 10 best 55 gallon drum transfer pumps that cater to a variety of needs and preferences. We'll discuss key features to look for, such as flow rates, compatibility with different fluids, and ease of use. Understanding these factors will not only help you choose the right pump but will also improve the overall efficiency of your fluid transfer processes. With the right 55 gallon drum transfer pump at your disposal, you can ensure that your operations run smoothly and effectively, minimizing waste and maximizing productivity.

Overview of 55 Gallon Drum Transfer Pumps and Their Applications

55-gallon drum transfer pumps are essential tools for efficiently moving liquids from larger containers to smaller vessels or directly into systems. These pumps are widely utilized in various industries, including manufacturing, automotive, agriculture, and chemical processing, where fluid management is crucial. Their design allows for safe and rapid transfer of fluids, minimizing waste and reducing the potential for spills. Depending on the specific application, different types of pumps—such as manual, electric, or pneumatic—can be used to meet varying needs.

When selecting a drum transfer pump, it’s important to consider the fluid being transferred, as certain materials may require specialized pumps for safe handling. Additionally, think about the volume and speed of transfer required for your operation. Regular maintenance is also key to ensuring pump efficiency and longevity; lubricating moving parts and checking seals can prevent leaks and operational failures.

Tips: Always use pumps that are compatible with the specific fluid types you are working with to avoid degradation or contamination. When transferring chemicals or oils, ensure you have safety gear on hand to handle any potential spills. Lastly, testing the pump's performance before deploying it for larger jobs can help identify any issues that might arise during operation.

Key Features to Consider When Selecting a Transfer Pump

When selecting a transfer pump for 55-gallon drums, several key features should be considered to ensure efficient fluid transfer. Firstly, the pump’s compatibility with various fluids is critical. Some pumps are designed specifically for thin liquids, while others can handle thicker substances or variations in viscosity. Choosing a pump that aligns with the types of chemicals or oils you will be transferring can prevent potential breakdowns or safety issues.

Another important feature is the flow rate of the pump. Depending on your needs—whether rapid transfer or a more controlled pace—a pump with adjustable flow rates might be ideal. It can facilitate different types of jobs, from quick transfers in a busy workshop to more precise operations in a laboratory setting. Additionally, look for features such as automatic shut-off systems, which help prevent spills and ensure user safety during operation.

Tips: When evaluating transfer pumps, pay attention to the material construction. Pumps made of corrosion-resistant materials, such as stainless steel or high-density polyethylene, can prolong the lifespan of the pump when working with harsh chemicals. Always check the ease of installation and portability, ensuring that the pump can be easily connected to drum openings and moved to different locations as necessary.

Top 10 Transfer Pumps: Performance and Efficiency Comparison

When selecting a transfer pump for 55-gallon drums, performance and efficiency should be the primary considerations. Industry reports indicate that centrifugal pumps are often the go-to choice for fluid transfer due to their ability to handle large volumes with lower energy consumption. According to a study by the Fluid Power Journal, the most efficient models can deliver up to 90% of energy used directly to the fluid, translating into significant cost savings for businesses over time. Additionally, the output rate of different pumps varies widely; some models can achieve flow rates exceeding 20 gallons per minute, making them ideal for high-demand applications.

In evaluating efficiency, it's important to assess the pump's power source as well. Electric pumps tend to offer quieter operation and must be correctly matched with the viscosity of the fluid to prevent cavitation, which can lead to performance drops and equipment damage. A comprehensive efficiency analysis can lead to identifying pumps that require minimal maintenance, as documented in the International Journal of Fluid Mechanics, where regular maintenance improved pump lifespan by up to 30%.

Tips: Always consider the fluid's characteristics before choosing a pump; higher viscosity liquids may require specialized transfer pumps. Additionally, check for features like automatic shut-off and built-in filters to enhance both safety and performance during operation. When integrating these pumps into your workflow, look for pumps with compliance certifications to ensure industry standards are met.

Performance Comparison of Top 10 Best 55 Gallon Drum Transfer Pumps

This chart illustrates the flow rate in gallons per minute (GPM) for the top 10 best 55-gallon drum transfer pumps. The performance comparison highlights the efficiency of each pump, providing insight into their capabilities for fluid transfer.

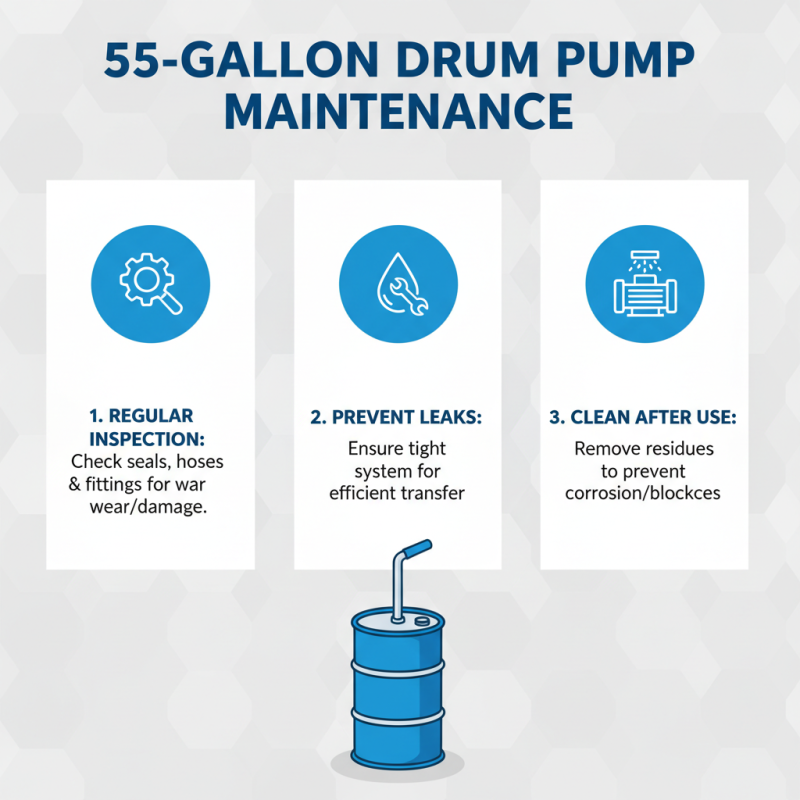

Maintenance Tips for Longevity of Your Transfer Pump

Proper maintenance of your 55-gallon drum transfer pump is essential for ensuring its longevity and optimal performance. One key aspect of maintenance is regular inspection of the pump components for wear or damage. Frequent checks of seals, hoses, and fittings can help prevent leaks and ensure a tight system that provides efficient fluid transfer. It's advisable to clean the pump after each use to remove any residues that might cause corrosion or blockages if left unattended.

Additionally, lubricating the moving parts according to the manufacturer's guidelines can extend the lifespan of your transfer pump. Using the correct type of lubricant reduces friction and wear, allowing your pump to operate smoothly. Ensure you store the pump in a clean, dry environment to protect it from environmental factors that could lead to degradation, such as excessive moisture or dust accumulation. Following these simple yet effective maintenance practices will help maintain your pump in top condition for many years of reliable use.

Safety Considerations During Fluid Transfer Operations

When conducting fluid transfer operations using 55-gallon drums, safety is paramount. According to the Occupational Safety and Health Administration (OSHA), improper handling and transferring of fluids can lead to serious accidents, including spills and exposure to hazardous materials. A key aspect of safety is ensuring that effective personal protective equipment (PPE) is used, including gloves, goggles, and respirators when necessary. Furthermore, industry reports suggest that training workers on the proper procedures for operating transfer pumps can significantly reduce incidents—organizations that implement comprehensive training programs report a 40% decrease in fluid transfer-related accidents.

Another critical safety consideration is the environmental impact of fluid transfers. The Environmental Protection Agency (EPA) highlights that leaks and spills can result in substantial fines and remediation costs. Implementing secondary containment systems, such as spill trays or bunds, can provide a buffer against accidental leaks, ensuring that any spillage is contained. Moreover, utilizing transfer pumps that are specifically designed to minimize splash-back and vapor release is essential. Reports indicate that using appropriate equipment can lower the risks associated with volatile compounds, helping to create a safer working environment while adhering to recommended safety standards. Prioritizing safety not only protects employees but also safeguards against environmental contamination, making it a crucial element in fluid transfer operations.

Related Posts

-

Top 10 Best Barrel Transfer Pumps for Efficient Liquid Transfer

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Understanding the Benefits of Using Electric Drum Pumps in Industrial Applications

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com