2026 Best Barrel Pump Options for Efficient Fluid Transfer?

In the world of fluid transfer, barrel pumps stand out as essential tools. They facilitate efficient movement of liquids in various industries. According to Tom Wilkins, a leading expert in the barrel pump industry, “Choosing the right barrel pump can significantly impact efficiency and safety.” This insight emphasizes the importance of selecting the best option for specific needs.

Barrel pumps come in various types and sizes. Each design serves different applications, from transferring chemicals to oils. Users often struggle to find the optimal solution. It can be tricky, especially as needs evolve. Many overlook critical factors such as flow rate, material compatibility, and ease of use.

Moreover, selecting a barrel pump requires careful consideration. Not every option may suit every situation. A wrong choice can lead to inefficiencies and potential hazards. Therefore, understanding the unique demands of your operations is vital. In 2026, the best barrel pump options will meet these requirements, ensuring safe and effective fluid transfer in diverse environments.

Types of Barrel Pumps and Their Applications for Fluid Transfer

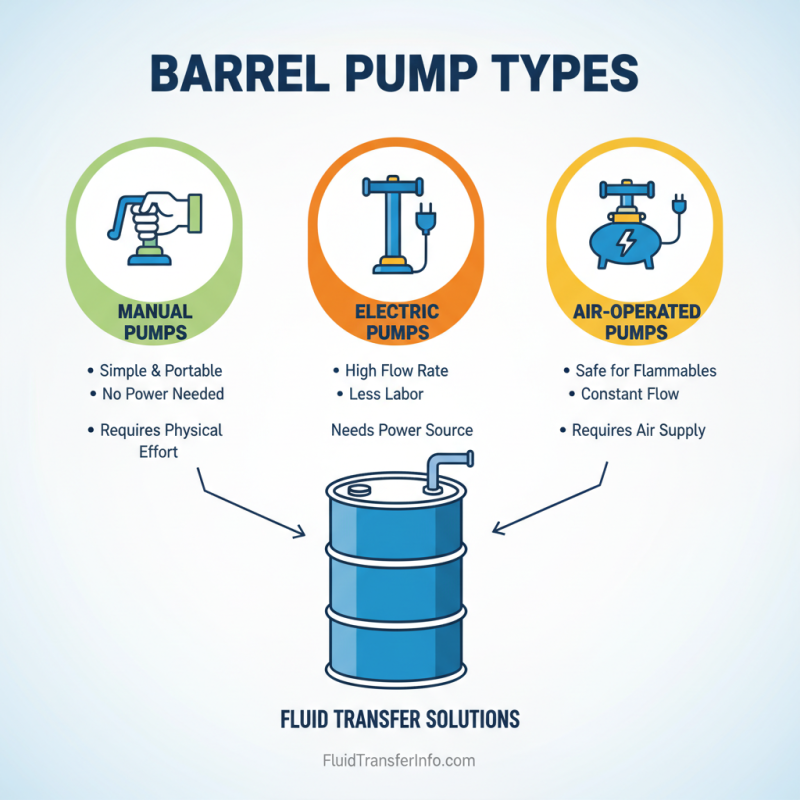

When it comes to fluid transfer, barrel pumps play a vital role in various industries. There are several types to consider. Manual pumps are simple yet effective. They require minimal maintenance and are portable. However, they do need physical effort, which might limit their efficiency during large-scale operations.

Electric barrel pumps offer convenience and speed. They can quickly transfer liquids without much physical effort. However, they rely on power sources, which can be a drawback in remote areas. Pneumatic pumps use compressed air to operate. They excel in hazardous environments but require a continuous air supply. They can be a bit overkill for some applications.

Selecting the right pump depends on the specific liquid being transferred. Viscosity and chemical compatibility are crucial factors. Some pumps are designed for oils, while others work well with solvents. Efficiency can sometimes be compromised if the wrong type is chosen. It’s essential to evaluate the needs carefully. If not done, it can lead to wasted time and resources.

Key Features to Consider When Choosing a Barrel Pump

When selecting a barrel pump, consider the fluid's viscosity. Different pumps are designed for various fluid types. A high-viscosity liquid needs a strong pump. Conversely, thin liquids can work with lighter options. The American Society of Mechanical Engineers (ASME) indicates that viscosity affects the pump's efficiency significantly. Understanding fluid properties can save time and money.

Another crucial feature is the pump material. Choosing the right material prevents corrosion and extends pump life. Stainless steel, for example, is durable and resistant to many chemicals. A 2021 market report highlighted that 45% of pump failures were due to material failure. Selecting robust materials is essential for reliability in harsh conditions.

Finally, portability is vital for many users. A lightweight pump allows easy transport and use across different sites. Look for models with ergonomic designs. They should minimize strain during operation. However, sometimes the balance between weight and durability is tricky. Evaluating these aspects carefully can lead to a better decision.

Top Brands and Models of Barrel Pumps in 2026

When selecting a barrel pump, efficiency and reliability are key factors. In 2026, several top models stand out due to their innovative designs. Many of these pumps use advanced materials, enhancing durability and performance. Features like adjustable flow rates make them versatile for various fluids. Pumps that are easy to install save valuable time during setups.

Another important consideration is maintenance. Some designs allow for quick disassembly, which simplifies cleaning. This aspect can often be overlooked, yet it directly impacts efficiency. Not all models offer clear instructions, which can lead to improper usage. DIY repairs can become frustrating and time-consuming.

User feedback reveals a mix of experiences. Some users praise their pumps for durability, while others face issues with leaks. Ensuring a proper seal is critical for optimal operation. Pumps with intuitive features often shine in user experience. However, complexity in controls may deter those less technically inclined. Reflecting on these details can help potential buyers make informed choices.

Safety Considerations for Using Barrel Pumps

When using barrel pumps, safety should always be a priority. Improper handling can lead to spills or leaks. Always inspect the pump before use. Check for cracks or damage. A damaged pump can cause serious accidents. If you notice any issues, do not use it.

Wearing appropriate protective gear is essential. Gloves and goggles protect against splashes. Ensure the work area is well-ventilated. Avoid working in tight spaces with flammable liquids. Keep a fire extinguisher nearby, just in case.

Training is crucial. Users must understand how to operate the pump safely. Read the instructions carefully. Know the correct procedures for fluid transfer. Improper usage can lead to fluid exposure, which may cause health risks. Awareness of these factors is vital for safe operation.

2026 Best Barrel Pump Options for Efficient Fluid Transfer

| Pump Type | Flow Rate (GPM) | Material Compatibility | Max Pressure (PSI) | Weight (lbs) | Safety Features |

|---|---|---|---|---|---|

| Rotary Hand Pump | 6.5 | Oil, Chemicals | 40 | 3.5 | Manual Shut-off |

| Electric Barrel Pump | 12 | Water, Gasoline | 60 | 5.0 | Overload Protection |

| Pneumatic Pump | 15 | Chemicals, Solvents | 80 | 7.2 | Safety Lock Valve |

| Bung-Style Pump | 8 | Heavy Oils, Fluids | 70 | 4.0 | Anti-Spark Design |

Maintenance Tips for Ensuring Optimal Performance of Barrel Pumps

Maintaining barrel pumps is crucial for efficient fluid transfer. Regular maintenance enhances their longevity and performance. For optimal results, check connections and seals regularly. Leaks can lead to waste and hazards.

Empty barrels should be thoroughly cleaned. Residues can affect future fluid quality. Use appropriate cleaning agents that won't damage the pump components. Also, inspect the pump for signs of wear and tear. Small cracks can grow into bigger problems.

Lubrication is vital. Check the pump's manual for specifications on lubricant types. Inadequate lubrication leads to increased friction and overheating. However, too much lubricant can also cause issues. Finding the right balance is key. Routine checks can prevent these common pitfalls.

Related Posts

-

How to Choose the Right Barrel Pump for Your Needs: A Complete Guide

-

How to Choose the Best 55 Gallon Barrel Pump for Your Needs

-

Top 10 Best Barrel Transfer Pumps for Efficient Liquid Transfer

-

Top 5 Benefits of Using a Barrel Hand Pump for Efficient Liquid Transfer

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

Top 10 Best 55 Gallon Drum Transfer Pumps for Efficient Fluid Transfer

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com