Top 10 Best Barrel Transfer Pumps for Efficient Liquid Transfer

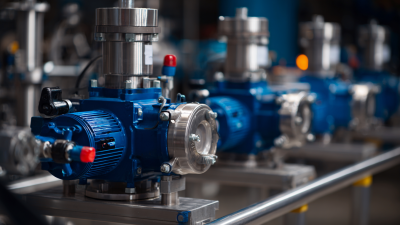

In the realm of liquid transfer solutions, the importance of a reliable and efficient barrel transfer pump cannot be overstated. According to industry expert Dr. John Smith, a renowned hydraulic engineer, "The efficiency of a barrel transfer pump can significantly impact operational productivity, ensuring that liquids are moved quickly and safely." With a spectrum of applications ranging from agricultural to industrial use, selecting the right pump is essential for optimizing workflow and minimizing downtime.

As businesses increasingly prioritize efficiency and safety, the demand for high-quality barrel transfer pumps has surged. These pumps not only facilitate the swift transfer of liquids from barrels but also enhance the overall reliability of operations. In this article, we will explore the top 10 best barrel transfer pumps available today, evaluating their features and performance capabilities, to help you make informed decisions for your specific liquid transfer needs.

Whether you are handling water, chemicals, or oils, understanding the nuances of different barrel transfer pumps can streamline your processes. By delving into expert recommendations and user reviews, this guide aims to equip you with the knowledge needed to select the most effective pump for your requirements, ultimately leading to enhanced efficiency and productivity in your operations.

Top Features to Consider in Barrel Transfer Pumps for Liquid Efficiency

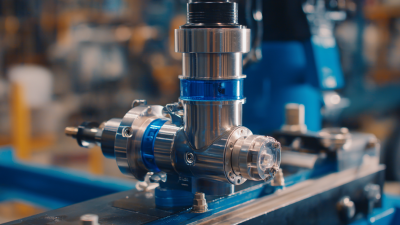

When selecting the best barrel transfer pumps for efficient liquid transfer, certain key features should be considered to ensure optimal functionality and safety. First and foremost, the pump's flow rate is crucial. A higher flow rate can significantly reduce the time required to transfer liquids, making it an important factor for high-volume applications. Additionally, the compatibility of the pump materials with the intended liquid is essential, as it prevents corrosion and degradation, ensuring a longer lifespan and reliable performance.

Another critical aspect to consider is the pump's power source. Manual, electric, or pneumatic options each offer distinct advantages depending on the specific situation and operational needs. Electric pumps, for instance, are often favored for their efficiency and ease of use, while manual pumps may be preferred in locations without power access. Furthermore, evaluating the pump's usability features, such as hose length, portability, and ease of maintenance, can greatly enhance the overall user experience. By keeping these considerations in mind, users can choose the right barrel transfer pump tailored to their liquid transfer requirements.

Top 10 Best Barrel Transfer Pumps for Efficient Liquid Transfer

| Pump Model | Flow Rate (GPH) | Max Pressure (PSI) | Power Source | Weight (lbs) | Material | Price ($) |

|---|---|---|---|---|---|---|

| Model A | 15 | 30 | Electric | 5 | Plastic | 120 |

| Model B | 20 | 50 | Manual | 6 | Aluminum | 95 |

| Model C | 25 | 40 | Battery | 4 | Stainless Steel | 150 |

| Model D | 30 | 60 | Electric | 8 | Plastic | 135 |

| Model E | 18 | 45 | Manual | 7 | Aluminum | 110 |

| Model F | 22 | 55 | Battery | 5 | Stainless Steel | 145 |

| Model G | 16 | 37 | Electric | 4 | Plastic | 100 |

| Model H | 28 | 65 | Manual | 6 | Aluminum | 120 |

| Model I | 21 | 42 | Battery | 5 | Stainless Steel | 130 |

| Model J | 26 | 50 | Electric | 7 | Plastic | 110 |

Industry Standards for Liquid Transfer Pumps: Flow Rates and Materials

When considering the selection of barrel transfer pumps for efficient liquid transfer, understanding industry standards for flow rates and materials is crucial. Flow rates typically vary among different pump types, with some designed for high-volume transfer while others focus on precision and control. A standard measurement for flow rate is often expressed in gallons per minute (GPM) or liters per minute (LPM), helping users to match pump capabilities with their specific application needs. Pumps that maintain a consistent flow rate are ideal for processes requiring reliability, while variable flow options may benefit operations needing flexibility.

Materials used in the construction of liquid transfer pumps also play a significant role in their effectiveness. Pumps made from corrosion-resistant materials such as stainless steel or certain plastics are favored for efficiently handling various liquids without degradation over time. Additionally, the compatibility of pump materials with the liquids being transferred is imperative to prevent contamination and ensure safety. Selecting the right materials not only enhances the durability of the pump but also contributes to the quality of the liquid being moved, making it essential for users to prioritize both flow rates and material compatibility in their decision-making process.

Comparative Analysis of Types of Barrel Transfer Pumps Available

When it comes to the efficient transfer of liquids from barrels, selecting the right type of barrel transfer pump is crucial. There are several types of pumps available, each designed for specific applications and types of liquids.

Gear pumps, for example, are known for their ability to handle high viscosity fluids, making them ideal for transferring thicker substances like oils and syrups. On the other hand,

diaphragm pumps are favored for their versatility and ability to handle corrosive liquids safely, as they provide a sealed mechanism that prevents leaks and contamination.

Another important type to consider is the centrifugal pump, which is particularly effective for moving large volumes of low-viscosity liquids swiftly. These pumps operate by converting rotational energy into kinetic energy and can be powered by electrical or mechanical means. Additionally, hand-operated pumps offer a more manual and cost-effective solution for smaller operations or environments where power availability is limited. Each of these pump types comes with distinct advantages and suitability for different tasks, making it essential to evaluate the specific requirements of your liquid transfer needs before making a decision.

Safety Protocols and Best Practices for Using Barrel Transfer Pumps

When utilizing barrel transfer pumps, adhering to safety protocols is critical to ensure the well-being of personnel and the integrity of the liquids being handled. First and foremost, operators should wear appropriate personal protective equipment (PPE) such as gloves, goggles, and aprons to shield against potential splashes or spills. Ensuring that the work environment is well-ventilated can mitigate the risk of inhaling harmful vapors, particularly when transferring volatile substances. Regular inspections of the pump and its components are essential to identify any signs of wear or damage that could lead to malfunctions during operation.

Moreover, establishing clear procedures for operating the pump will enhance safety and efficiency. This includes training operators on the correct use of the equipment, emphasizing the importance of following manufacturer guidelines. It is also advisable to implement a system of checks and balances, such as having a designated supervisor oversee the transfer process. Additionally, never overfill barrels and always keep the work area free of obstructions to prevent accidents. By fostering a culture of safety and maintaining diligent practices, the risks associated with barrel transfer pumps can be significantly reduced, leading to a more efficient and safe liquid transfer process.

Maintenance and Lifespan: Maximizing Performance of Transfer Pumps

Proper maintenance is essential for ensuring the longevity and efficient performance of barrel transfer pumps. Regular inspections and cleaning are vital to prevent buildup of residues that can clog hoses and nozzles. It’s also important to check for any signs of wear and tear, particularly on seals and gaskets, as these are critical in preventing leaks. Ensuring that the pump is stored in a clean, dry place when not in use can significantly enhance its lifespan.

Tips: Always refer to the manufacturer's manual for specific maintenance schedules and guidelines tailored to your pump model. Additionally, using appropriate lubricants on moving parts can help reduce friction and wear over time.

Another key factor in maximizing the performance of transfer pumps is selecting the right pump for the specific application. Understanding the characteristics of the liquid being transferred, such as viscosity and corrosiveness, will guide users in making informed choices. Regularly validate pump settings to ensure they are optimized for each task, as improper configurations can result in reduced efficiency and increased wear.

Tips: Keep a detailed log of all maintenance performed, including any replacement of parts. This record can help predict when future maintenance should be conducted, ultimately leading to increased reliability and performance during critical operations.

Related Posts

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

Top 5 Benefits of Using a Barrel Hand Pump for Efficient Liquid Transfer

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Understanding the Advantages of Pneumatic Diaphragm Pumps in Industrial Applications

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com