How to Choose the Best Stainless Steel Drum Pump for Your Needs

When it comes to transferring liquids, especially in industrial settings, having the right equipment is crucial. A stainless steel drum pump stands out as an essential tool for efficiently moving viscous and corrosive fluids. These pumps are not only durable but also resistant to rust and corrosion, making them ideal for various applications in factories, warehouses, and laboratories. However, with a variety of options available on the market, choosing the best stainless steel drum pump for your specific needs can be a daunting task.

First and foremost, it is important to consider the type of liquids you will be pumping, as different pumps are designed to handle specific viscosities and chemical compositions. Additionally, the size and design of the pump should align with the dimensions of your storage drums for a proper fit. Furthermore, understanding the pump's flow rate, ease of use, and maintenance requirements can significantly enhance your operational efficiency and effectiveness. In this guide, we will explore key factors to help you make an informed decision and find the perfect stainless steel drum pump that meets your operational needs and enhances productivity.

Understanding Stainless Steel Drum Pumps and Their Applications

Stainless steel drum pumps are essential tools for transferring liquids efficiently and safely across various industries. Their construction from corrosion-resistant materials makes them ideal for handling a wide range of substances, from chemicals to food-grade liquids. These pumps are particularly valued in manufacturing, pharmaceuticals, and food processing, where maintaining hygiene and preventing contamination are critical. Understanding the different applications of stainless steel drum pumps can help users select the right model for their specific needs.

In addition to their versatile applications, stainless steel drum pumps also come with various features to cater to different operational requirements. For instance, some models are designed for high flow rates, making them suitable for large-scale operations, while others might focus on more precise, controlled dispensing to cater to smaller quantities. Users should also consider aspects such as the pump's compatibility with the liquids being transferred, ease of maintenance, and portability, as these factors can significantly influence overall efficiency and safety during operation. Proper knowledge of these features and applications ensures that users can make informed decisions when selecting the best stainless steel drum pump for their needs.

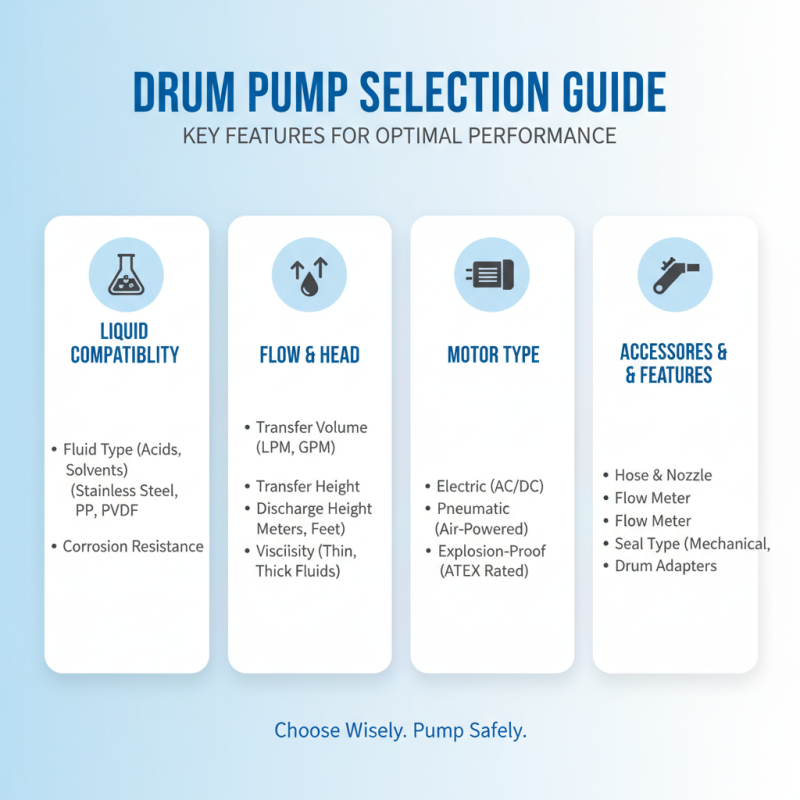

Key Features to Consider When Selecting a Drum Pump

When selecting a stainless steel drum pump, there are several key features to consider to ensure you choose the best one for your specific needs. One of the primary considerations is the pump's compatibility with the liquids you intend to transfer. Different fluids may require varying materials to prevent corrosion or contamination, so ensure the pump is designed to handle the specific chemical properties of your liquids.

Another critical feature is the pump's flow rate and discharge capabilities. This will determine how quickly and effectively you can transfer liquids. Consider the size of the tank or drum you will be using the pump with, as well as your intended application. A higher flow rate might be beneficial for larger operations, while a more moderate flow might suffice for smaller tasks.

Tips: Always check the pump’s specifications for maximum viscosity, as thicker liquids may require more robust pump systems. Additionally, look for ergonomic handles and lightweight designs for ease of use, which can make a significant difference during repetitive tasks. Lastly, ensure that the pump meets the necessary safety standards to safeguard against leaks and spills.

Assessing Pump Compatibility with Different Liquids

When selecting a stainless steel drum pump, assessing its compatibility with different liquids is crucial for optimal performance and safety. Many industries utilize various chemicals, and the pump material's resistance to corrosion, temperature, and pressure must align with the liquid being transferred. According to a recent report by the Fluid Handling Industry Association, over 70% of pump failures are attributed to material incompatibility, highlighting the importance of thorough evaluation before making a purchase.

Tips for choosing a compatible pump include performing a compatibility test with the liquid in question, reviewing chemical resistance charts provided by manufacturers, and considering factors such as viscosity and temperature. For instance, pumps designed for transferring aggressive acids or solvents should be made from high-grade stainless steel that can withstand their corrosive properties. Additionally, understanding the flow rates required for your application can impact your choice of pump size and type, ensuring efficient and safe operations.

Moreover, always take into account the pH level of the liquid, as it can significantly affect the steel's durability over time. An industry survey indicates that around 40% of users do not check pH compatibility, which can lead to premature pump failure. Regular maintenance and monitoring can enhance the longevity of your pump, but starting with the right compatibility assessment is the key to preventing costly downtime.

Stainless Steel Drum Pump Compatibility with Different Liquids

Evaluating Power Sources and Motor Options for Drum Pumps

When selecting a stainless steel drum pump, one of the most critical considerations is the power source and motor options available. Drum pumps can be powered through various sources, including electric motors, air-driven systems, or manual mechanisms. According to industry research, electric-powered pumps are prevalent due to their efficiency and ease of use, providing faster transfer rates, while pneumatic options are favored in environments where electrical safety is a concern, such as in wet or explosive atmospheres.

Electric motor options vary significantly, with continuous-duty motors being ideal for high-volume applications. A study published by the Fluid Handling Journal highlights that pumps equipped with variable frequency drives can optimize energy consumption and adapt to fluctuating flow demands, leading to savings of up to 30% on energy costs. In contrast, air-driven motors, while typically less efficient for larger operations, offer significant benefits in terms of maintenance and operational flexibility, especially in remote areas where electrical supply may be limited.

**Tips:** When choosing a power source, consider the specific fluid being transferred and the environment in which the pump will operate. For instance, corrosive substances may require more robust solutions. Additionally, evaluate the total cost of ownership, which incorporates initial expenses, maintenance costs, and energy consumption over time to ensure you select the most suitable pump for your needs.

How to Choose the Best Stainless Steel Drum Pump for Your Needs - Evaluating Power Sources and Motor Options for Drum Pumps

| Pump Type | Power Source | Motor Type | Max Flow Rate (GPM) | Max Head Height (Feet) | Suitable Liquids | Price Range ($) |

|---|---|---|---|---|---|---|

| Electric Drum Pump | Electric | AC Motor | 15 | 20 | Water, Chemicals | 150 - 300 |

| Manual Drum Pump | Manual | N/A | 5 | 10 | Water, Oil | 30 - 100 |

| Pneumatic Drum Pump | Air Power | Pneumatic Motor | 20 | 30 | Chemicals, Water | 200 - 400 |

| Battery Operated Pump | Battery | DC Motor | 10 | 15 | Water, Diesel | 100 - 250 |

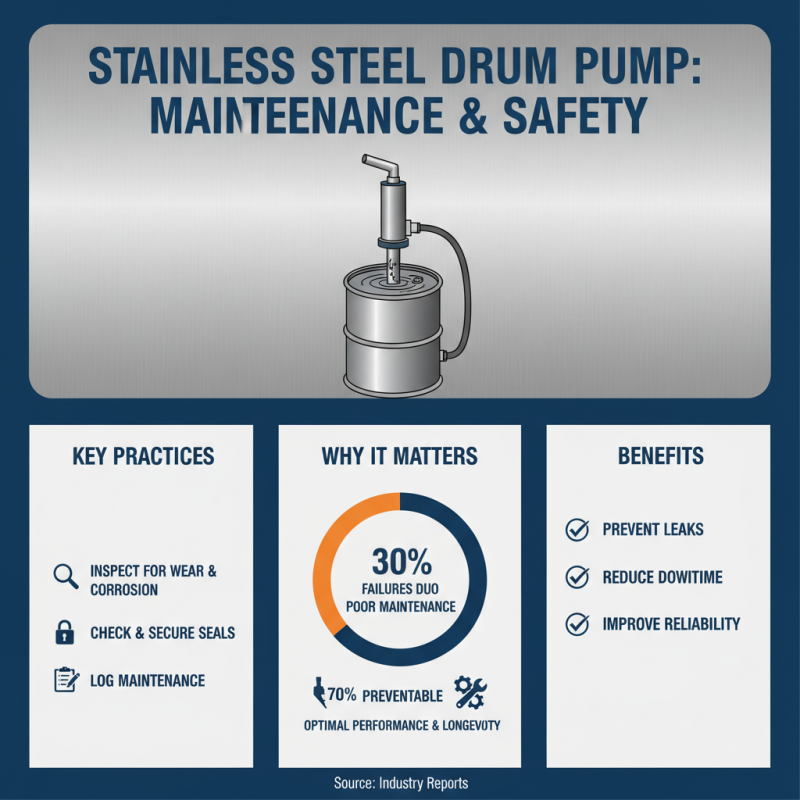

Maintenance and Safety Tips for Utilizing Stainless Steel Drum Pumps

When utilizing stainless steel drum pumps, proper maintenance and safety practices are essential to ensure their optimal performance and longevity. Regularly inspecting the pump for wear and tear, checking for corrosion, and ensuring all seals are properly secured can prevent leaks and operational failures. According to industry reports, approximately 30% of pump failures are attributed to inadequate maintenance. Keeping a log of maintenance activities can also help track performance and identify any recurring issues.

Safety is paramount when operating stainless steel drum pumps, especially in industrial settings where hazardous materials may be involved. Always utilize appropriate personal protective equipment (PPE), including gloves and goggles, to prevent injury from splashes or spills. It is crucial to have a spill containment plan in place, as data from environmental safety audits reveal that poorly managed spills can lead to costly fines and regulatory issues.

Tips for enhancing safety include ensuring the workspace is well-ventilated and free of obstructions that could cause accidents. Additionally, train all operators on emergency protocols and proper pump handling techniques. Regular safety drills can bolster preparedness and contribute to a safer working environment overall. By prioritizing maintenance and safety, users can maximize the effectiveness of their stainless steel drum pumps while minimizing risks.

Related Posts

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Understanding the Benefits of Using Electric Drum Pumps in Industrial Applications

-

Discover the Hidden Benefits of Using an Air Drum Pump for Fluid Transfer

-

Understanding the Advantages of Pneumatic Diaphragm Pumps in Industrial Applications

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com