How to Choose the Right Barrel Pump for Your Needs: A Complete Guide

When it comes to transporting liquids from a barrel, a barrel pump is an essential tool that can significantly streamline the process. Choosing the right barrel pump can be overwhelming given the variety of options available on the market today. Understanding the different types, materials, and features that barrel pumps offer is crucial for ensuring that you select the best one for your specific needs. Whether you are handling oils, chemicals, or other viscous liquids, the right pump can enhance efficiency and safety in your operations.

In this complete guide, we will delve into the key considerations to keep in mind when selecting a barrel pump. From understanding the intended application to evaluating the capacity and materials best suited for your liquid, our comprehensive outline will equip you with the knowledge needed to make an informed decision. With the right approach, finding a barrel pump that meets your requirements will be both manageable and rewarding, ensuring you maximize productivity while maintaining safety standards.

Understanding Different Types of Barrel Pumps and Their Applications

When selecting a barrel pump, it's essential to understand the various types and their specific applications to make an informed decision. There are primarily three types of barrel pumps: manual, electric, and air-operated. Manual pumps are typically used for small-scale applications where minimal pressure is required. They are easy to operate and do not rely on electricity, making them ideal for remote locations or emergency situations. Electric pumps, on the other hand, offer a more efficient and faster solution for larger volumes and continuous operation, making them suitable for industrial environments. Air-operated pumps utilize compressed air and are effective for transferring viscous fluids, offering higher flow rates while minimizing the risks of ignition in flammable environments.

Tips: Consider the viscosity of the fluid you'll be transferring, as this will significantly influence your pump choice. Manual pumps may struggle with thick liquids, while air-operated pumps can handle them more effectively. Additionally, pay attention to the pump's material construction; corrosion-resistant materials are crucial when dealing with chemicals or acidic substances to ensure longevity and prevent leaks.

Always evaluate the compatibility of the pump with the fluids being handled. Certain pumps are designed specifically for non-corrosive materials, while others can manage a wider range of chemicals. If you're unsure, consulting the manufacturer’s specifications or seeking expert advice can help you avoid potential mishaps and ensure optimal performance for your needs.

Key Factors to Consider When Selecting a Barrel Pump for Your Operations

When selecting a barrel pump for your operations, understanding key factors is essential to ensure efficiency and safety. Firstly, consider the fluid type you will be transferring. Research indicates that approximately 70% of fluid transfer incidents are related to incompatibility between the pump materials and the substances being pumped. Materials like polypropylene, stainless steel, or aluminum each have unique properties suited for different chemicals. For example, a survey by the Chemical Engineering journal highlights that untreated polypropylene is ideal for less aggressive chemicals, while stainless steel is preferred for corrosive substances.

Another critical factor is the pump's flow rate and viscosity capacity. According to industry studies, a pump's efficiency significantly drops if it is not suited to the viscosity of the fluid, leading to increased operational costs and maintenance issues. As a rule of thumb, choosing a pump with a flow rate that can handle at least 20% more than your operational requirements can provide a necessary buffer and prolong the pump's lifespan. Additionally, consider the power source—whether pneumatic, electric, or manual—as this can affect portability and convenience in various applications.

Finally, ease of maintenance and safety features should not be overlooked. Reports indicate that a user-friendly design enables faster maintenance turns, resulting in up to a 25% increase in overall productivity. Moreover, safety features such as anti-siphon provisions and explosion-proof designs are vital, particularly when handling hazardous materials. Therefore, conducting thorough research on these key factors will facilitate a more informed decision when choosing the right barrel pump for your needs.

Evaluating Flow Rates: How Pump Performance Affects Efficiency

When selecting a barrel pump, understanding flow rates is crucial for optimizing performance and efficiency. Flow rate, typically measured in gallons per minute (GPM), indicates how much fluid a pump can transfer over a given time. According to the Hydraulic Institute, an optimum flow rate aligns not only with the size of the barrel but also with the viscosity and specific characteristics of the fluid being pumped. For example, a pump transferring thicker fluids will typically operate less efficiently at higher flow rates, making it essential to match the pump type to the application requirements.

Moreover, the performance of a pump directly influences energy consumption and operational costs. A study by the U.S. Department of Energy highlighted that inefficient pumps could waste over 20% of their energy in industrial applications, emphasizing the need for careful selection based on flow rates. By evaluating the pump’s flow rate in relation to the viscosity and type of liquid, users can optimize their system’s efficiency, minimizing energy waste and ensuring effective operation. Therefore, determining the correct flow rate is not just about meeting minimum requirements; it’s about enhancing overall operational productivity and reducing unnecessary expenses.

Material Compatibility: Ensuring Chemical Resistance in Barrel Pump Selection

When selecting a barrel pump, one of the most critical factors to consider is material compatibility, which ensures that the pump can handle the specific chemicals it will be exposed to without degrading. Different materials, such as plastics, metals, or elastomers, have varying resistance to chemicals, making it essential to match the pump’s materials to the barrel contents. For instance, if you're dealing with corrosive substances, a pump made from chemical-resistant materials like polypropylene or PVDF would be advisable, as these materials can withstand harsh conditions and prevent leaks or failures.

Additionally, it's important to evaluate not just the chemical composition but also the concentration and temperature of the liquids involved. Some materials may perform adequately at room temperature but could break down or lose integrity under high temperatures or with concentrated acids. Conducting compatibility tests or consulting with manufacturers for guidance on chemical resistance charts can lead to better-informed decisions. This careful assessment of material compatibility can significantly extend the lifespan of the pump, ensuring that it operates efficiently and safely within your specific application.

Material Compatibility in Barrel Pump Selection

Maintenance and Longevity: Best Practices for Barrel Pump Care and Use

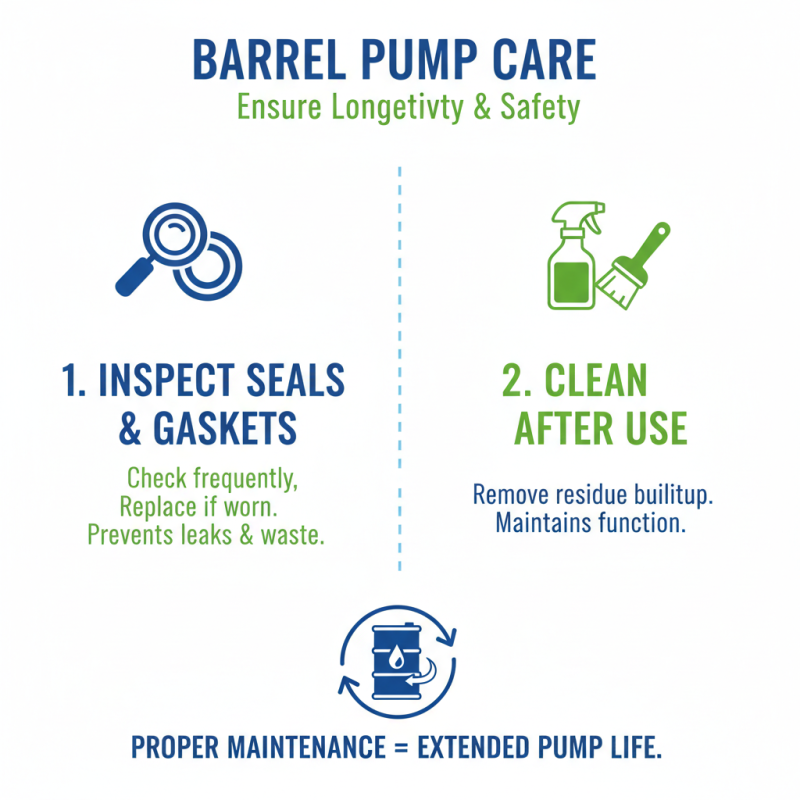

When it comes to maintaining and ensuring the longevity of barrel pumps, proper care is essential. One of the key practices is regular inspection of seals and gaskets. Over time, these components can wear out, leading to leaks that not only waste your fluid but can also pose safety risks. Make it a habit to check these parts frequently and replace them as needed. Additionally, after every use, clean the pump thoroughly to avoid residue buildup that could impair its function.

Tips: Always store your barrel pump in a dry, clean environment. This helps prevent corrosion and keeps the pump in optimal condition. If using the pump with corrosive liquids, ensure you are aware of compatibility to avoid damaging the materials.

Furthermore, proper lubrication of moving parts is crucial. Follow the manufacturer’s guidelines regarding the type of lubricant to use and how often to apply it. This practice minimizes friction and wear, extending the life of the pump. Regularly maintaining your barrel pump not only enhances performance but also saves you from costly replacements down the line.

Related Posts

-

Top 10 Best Barrel Transfer Pumps for Efficient Liquid Transfer

-

Top 5 Benefits of Using a Barrel Hand Pump for Efficient Liquid Transfer

-

How to Choose the Best 55 Gallon Barrel Pump for Your Needs

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

How to Choose the Best Stainless Steel Drum Pump for Your Needs

-

Top 10 Best 55 Gallon Drum Transfer Pumps for Efficient Fluid Transfer

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com