What is a Pneumatic Drum Pump and How Does It Work?

In the world of industrial fluid transfer, the pneumatic drum pump has emerged as a vital tool for efficiently moving liquids from drums and containers. Experts in the field, such as Dr. Alan Peterson, a leading authority on fluid dynamics, emphasize the significance of this equipment in various applications. Dr. Peterson states, "Pneumatic drum pumps not only streamline the transfer process but also enhance safety by minimizing spills and leaks."

Understanding how a pneumatic drum pump operates is crucial for industries that rely on precise and secure liquid handling. These pumps utilize compressed air to create suction, drawing liquids up and out of containers with ease. This method not only reduces the physical effort required but also ensures that even hazardous materials can be managed more safely. In an era where efficiency and safety are paramount, the pneumatic drum pump stands out as an indispensable solution that is well-adapted to the demands of modern manufacturing and chemical processing environments.

Understanding the Basics of Pneumatic Drum Pumps

Pneumatic drum pumps are specialized devices designed for transferring liquids, utilizing compressed air as the driving force. Understanding the basics of how these pumps operate can significantly enhance efficiency in a variety of industrial applications. Typically composed of a cylindrical pump body and a piston mechanism, pneumatic drum pumps are capable of moving fluids at high flow rates while maintaining a compact design. They are particularly valued in handling aggressive or viscous materials, including chemicals and oils, where traditional electric pumps may falter due to overheating or electric compatibility issues.

According to recent industry reports, the pneumatic pump market is expected to reach a valuation of USD 1.2 billion by 2025, driven by the growing need for effective solutions in industries such as automotive, food & beverage, and pharmaceuticals. Understanding the operational aspects can lead to improved performance; for instance, maintaining optimal air pressure is vital. Tips for users include regularly checking for leaks in air supply lines, as even minor leaks can lead to inefficiencies, and ensuring that the pump is suited to the viscosity of the fluids being transferred.

Additionally, proper maintenance is crucial for longevity and reliability. Frequent inspections of the pump components—such as seals and valves—can preemptively address wear and tear. Implementing a schedule for routine cleaning can also mitigate corrosion issues, thereby extending the life of the pump. By adhering to these practices, users can maximize the efficiency of pneumatic drum pumps, contributing to smoother operations across various applications.

Pneumatic Drum Pump Performance Metrics

This bar chart illustrates the performance metrics of a typical pneumatic drum pump, including flow rate, operating pressure, air consumption, and weight. This information is essential for understanding the capabilities and limitations of these pumps in various applications.

Components of a Pneumatic Drum Pump: An Overview

A pneumatic drum pump is an essential tool used in various industries for transferring liquids from drums or barrels. The design of a pneumatic drum pump consists of several key components that work together to facilitate the movement of fluids. At its core, the pump features a pneumatic motor that generates the suction necessary to draw fluid from the container. This motor is powered by compressed air, making it efficient and suitable for hazardous environments where electric pumps may pose safety risks.

The primary components of a pneumatic drum pump include the pump body, an air motor, and a control valve. The pump body is typically made of materials resistant to corrosion, which is crucial for handling various chemicals. The air motor transforms air pressure into mechanical energy, allowing the pump to create an adequate flow rate. According to a report by the Fluid Power Society, pneumatic pumps can achieve flow rates ranging from 5 to 100 gallons per minute, depending on the specific model and application, demonstrating their versatility across different sectors.

Additionally, the control valve integrated within the pump system allows users to regulate the flow and pressure of the fluid being transferred. This component is vital for achieving precise dispensing in industrial applications. Studies indicate that pneumatic pumps have been shown to provide higher efficiency and lower maintenance costs compared to their electric counterparts, making them an increasingly popular choice for businesses aiming to optimize their operational efficiency.

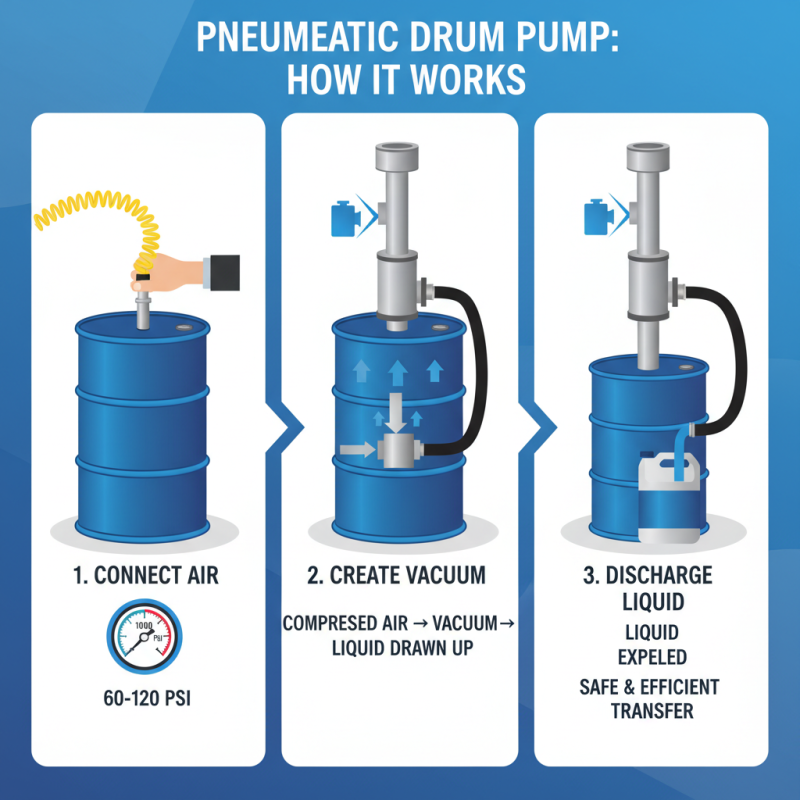

How Pneumatic Drum Pumps Operate: A Step-by-Step Guide

Pneumatic drum pumps are an essential tool in various industries for transferring liquids from barrels or drums. These pumps rely on compressed air to create a vacuum that draws the liquid into the pump and expels it through a discharge hose. The operation of a pneumatic drum pump can be broken down into several key steps. First, an operator connects the pump to a compressed air source, ensuring that the air pressure meets the manufacturer’s specifications. Most pneumatic drum pumps operate efficiently at pressures ranging from 60 to 120 psi, making them suitable for various applications.

Once connected, the operator lowers the pump into the drum and activates the air system. The compressed air enters the pump, causing the diaphragm or piston to move, which in turn creates a vacuum effect that pulls the liquid up from the bottom of the drum into the pump chamber. At this stage, the check valve prevents backflow, allowing only the liquid to advance. As the pump continues its cycle, the liquid is pushed out through the discharge outlet, enabling rapid and efficient transfer. Studies have shown that pneumatic drum pumps can achieve flow rates of up to 30 gallons per minute, significantly enhancing productivity in settings that require frequent drum emptying or liquid transfers.

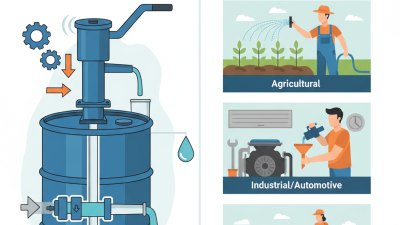

Applications and Benefits of Using Pneumatic Drum Pumps

Pneumatic drum pumps are versatile devices commonly used in various industries for transferring liquids efficiently and safely. These pumps are particularly effective for handling viscous fluids, chemicals, and other materials stored in drums, making them indispensable in manufacturing, automotive, and chemical processing sectors. Their operation relies on compressed air to create a vacuum that draws the liquid up and out of the drum, allowing for quick and effective transfer without the need for electric components.

One of the key benefits of pneumatic drum pumps is their ability to work in hazardous environments where electric pumps would pose risks of sparks or explosions. Additionally, their simplicity in design means that they can be easily maintained and operated. The use of pneumatic pumps also minimizes the chances of spills and contamination, protecting both the product and the environment.

Tips: When selecting a pneumatic drum pump, consider the viscosity and chemical compatibility of the liquid to ensure you choose the right materials for the pump components. Regular maintenance checks, including inspecting hoses and seals, can prevent leaks and prolong the pump’s lifespan. Always ensure you are using the appropriate air pressure settings for optimal performance and efficiency.

Maintenance Tips for Optimal Performance of Pneumatic Drum Pumps

Pneumatic drum pumps are essential tools for transferring liquids, particularly in industrial and chemical applications. To ensure these pumps operate at their best, regular maintenance is crucial. According to industry studies, proper maintenance can extend the lifespan of pneumatic pumps by up to 30%, significantly reducing downtime and repair costs.

One of the fundamental maintenance tips is to regularly inspect the wear components such as seals and diaphragms. These parts can degrade over time due to constant use and exposure to various chemicals. Monitoring these components for signs of wear and replacing them promptly can prevent leaks and ensure efficient operation. Additionally, lubricating moving parts with compatible oils is vital for reducing friction, which can lead to premature failure.

Another important tip is to keep the pump clean and free from contaminants. Dust and residue can accumulate, hindering the pump's performance. Incorporating a cleaning routine, particularly for the inlet and outlet areas, is essential to maintain optimal fluid transfer rates. Industry reports suggest that a clean pump can operate up to 15% more efficiently. By following these maintenance practices, users can achieve reliable performance and longevity from their pneumatic drum pumps.

Related Posts

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Discover the Hidden Benefits of Using an Air Drum Pump for Fluid Transfer

-

Why Choosing a Finish Thompson Drum Pump is Essential for Efficient Fluid Transfer

-

What is a 55 Gallon Hand Pump and How Does it Work Tips and Uses

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

The Ultimate Guide to Choosing the Right 3 Diaphragm Pump for Your Needs

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com