Top 10 Benefits of Electric Double Diaphragm Pumps?

The electric double diaphragm pump has gained significant attention in various industries due to its outstanding capabilities. John Smith, a renowned expert in hydraulic systems, emphasizes, "These pumps deliver reliable performance and efficiency." Companies are increasingly turning to this technology for fluid transfer applications.

Electric double diaphragm pumps are often celebrated for their simple design and minimal maintenance. They can handle a wide range of fluids, making them versatile. However, some users express concerns about their initial cost and potential operational limitations.

Despite these challenges, the benefits are compelling. They provide consistent flow rates, even with viscous fluids. This efficiency leads to reduced energy consumption over time. Exploring these advantages can help industries make informed decisions about adopting electric double diaphragm pumps for their operations.

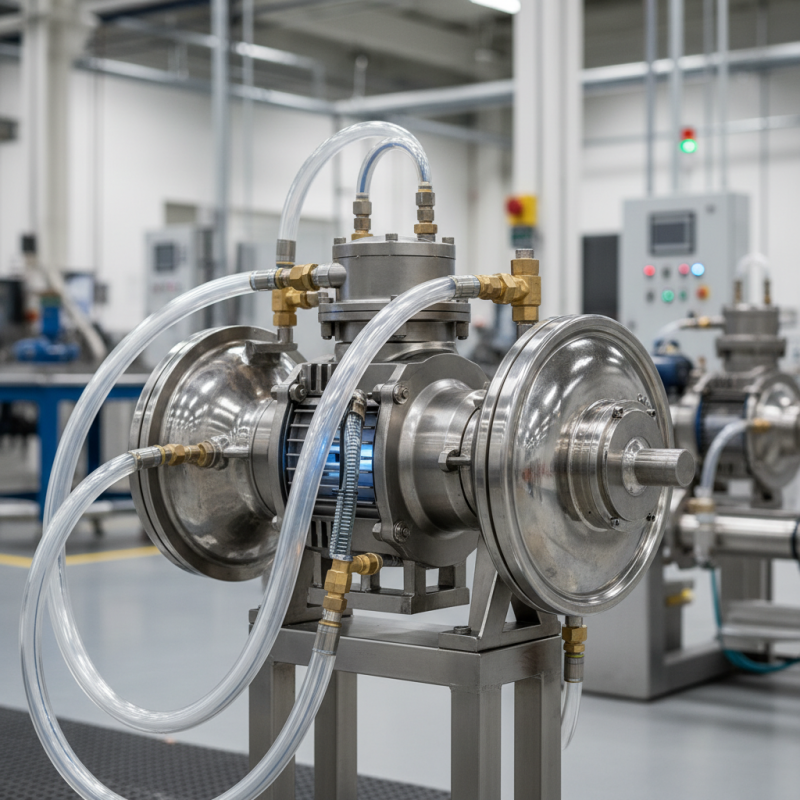

Overview of Electric Double Diaphragm Pumps

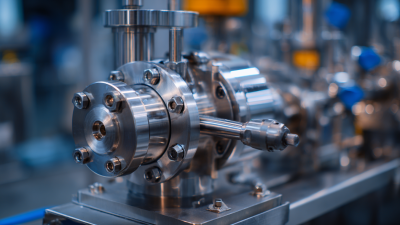

Electric double diaphragm pumps are versatile devices used in various industries. They rely on two diaphragms to create a pumping action. This design allows them to handle a wide range of fluids, including corrosive and viscous liquids. They are generally ideal for harsh environments. Many facilities benefit from their durability and reliability.

These pumps provide unique advantages. They operate without electricity, which reduces energy costs. They can self-prime, saving time during setup. Maintenance can be simple, though it’s essential not to neglect regular checks. Some users might struggle with initial installation and troubleshooting. Proper training can minimize these issues. Moreover, while they are robust, occasional wear and tear may arise, requiring attention. The balance between efficiency and upkeep is crucial.

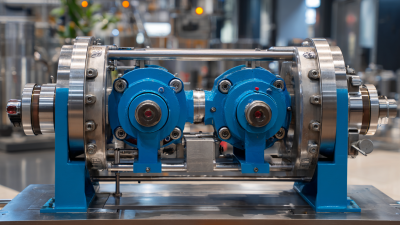

Advantages of Efficiency in Electric Double Diaphragm Pumps

Electric double diaphragm pumps have gained acclaim for their efficiency in various industries. One major advantage is their ability to handle different materials. A recent study showed that these pumps can achieve over over 90% volumetric efficiency. This means less wasted energy and more effective fluid transfer. Such efficiency reduces operational costs significantly over time.

Another benefit is their low maintenance requirements. A report from industry experts highlighted that these pumps generally require 40% less maintenance compared to traditional pumps. This is vital for businesses looking to minimize downtime. However, some users note that initial setup can be complex. Understanding the pump's operation is crucial for maximizing efficiency.

In situations where energy consumption is critical, electric diaphragm pumps excel. They consume power when needed, rather than continuously running. This leads to energy savings up to 30% compared to conventional pumps. Yet, users may find the cost of electric models higher initially. Balancing upfront costs and long-term savings can be tricky. It's essential to evaluate overall operational needs before making a decision.

Maintenance Ease and Reliability of Electric Double Diaphragm Pumps

Electric double diaphragm pumps are known for their reliability and ease of maintenance. These pumps are designed with fewer moving parts, which often leads to longer life spans. When you need to maintain them, the process is relatively straightforward. For instance, you can quickly access and replace diaphragms without specialized tools. This can save time and reduce downtime in operations.

Routine checks are still essential. Even though maintenance is simple, neglecting it can lead to performance issues. Monitoring the pumps for leaks or unusual noises is crucial. Sometimes, wear occurs unnoticed. It's also worth noting that proper cleaning can prevent issues from arising. Users must commit to regular inspections to ensure optimal functionality. This proactive approach often pays off in the long run.

Moreover, the versatility of electric double diaphragm pumps makes them suitable for various applications. They can handle a wide range of fluids, from viscous substances to slurries. However, the operating conditions should always be considered. Overloading the pump can lead to premature failure, leading to unexpected maintenance needs. Balancing performance and operational demands is a constant reflection for users.

Top 10 Benefits of Electric Double Diaphragm Pumps

This chart illustrates the top ten benefits of electric double diaphragm pumps, showcasing their effectiveness in maintenance ease, reliability, and various other advantages.

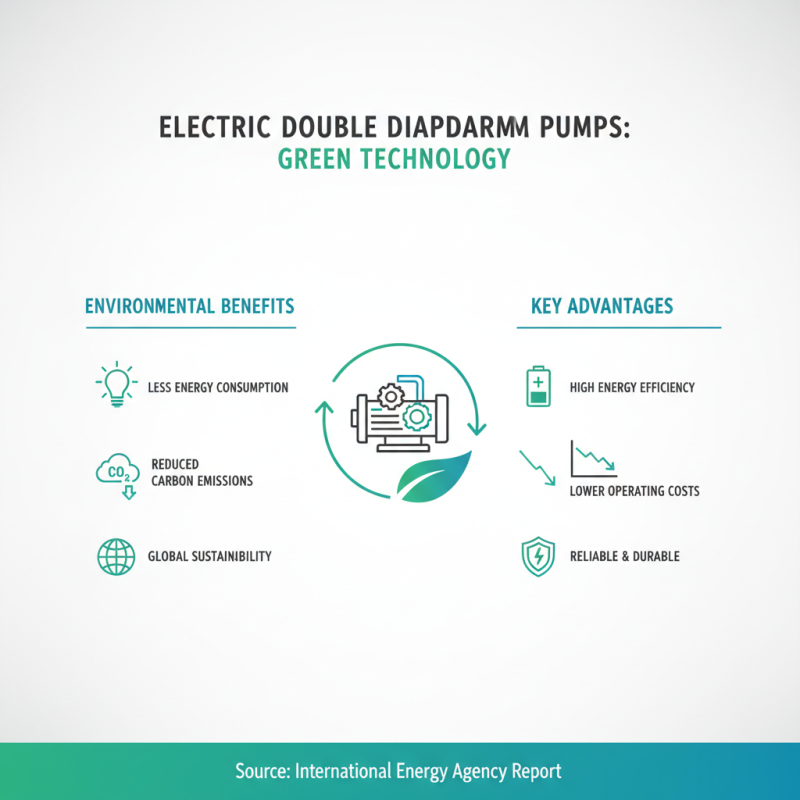

Environmental Benefits of Using Electric Double Diaphragm Pumps

Electric double diaphragm pumps (EDDP) serve as a vital technology for various industries. Their environmental benefits stand out significantly. According to a recent report by the International Energy Agency, EDDPs consume less energy than traditional pumps, reducing carbon emissions dramatically. This energy efficiency aligns with global sustainability goals.

These pumps are also known for minimizing waste. They operate with minimal leakage, thereby preventing hazardous substances from contaminating the environment. A study by the Environmental Protection Agency found that over 30% of traditional pump systems leak, causing severe environmental harm. EDDPs help mitigate this risk, promoting a cleaner industrial footprint.

Tips: Regular maintenance enhances the longevity of EDDPs, ensuring they remain efficient. Consider implementing a monitoring system to track pump performance. Small changes, like using these pumps, can lead to more substantial environmental impact. Make informed decisions in your operations. Every drop counts!

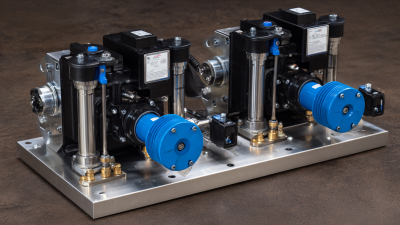

Versatility Across Industries for Electric Double Diaphragm Pumps

Electric double diaphragm pumps have gained significant traction across multiple industries, showcasing their versatility. They effectively handle a variety of fluids, from thick slurries to delicate chemicals. According to a market research report by Grand View Research, the global diaphragm pump market is projected to reach $6 billion by 2028. This growth signifies the increasing reliance on these pumps in sectors such as food processing, pharmaceuticals, and wastewater management.

In the food and beverage industry, these pumps enable precise transfer of ingredients without contamination. Their ability to operate dry and self-prime adds to their appeal. However, there are challenges. The need for regular maintenance can cause downtime, impacting productivity. Moreover, the pumps may not be suitable for handling abrasive materials, which could lead to wear and tear.

The pharmaceutical sector also benefits greatly from electric double diaphragm pumps. They meet stringent safety standards and provide reliable dosing. Yet, achieving consistent flow rates can sometimes be tricky. Small adjustments are often necessary to maintain desired outputs. Thus, while these pumps offer exceptional versatility, users must remain mindful of their limitations.

Related Posts

-

How to Choose the Right Yamada Diaphragm Pump for Your Application in 2025

-

Unlocking Efficiency: The Science Behind Performance Optimization in Electric Double Diaphragm Pumps

-

The Ultimate Guide to Choosing the Right 3 Diaphragm Pump for Your Needs

-

Why the Wilden Diaphragm Pump is the Best Choice for Reliable Fluid Transfer in Industrial Applications

-

10 Essential Tips for Choosing the Right Air Operated Double Diaphragm Pump

-

Why Choosing a Finish Thompson Drum Pump is Essential for Efficient Fluid Transfer

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com