2025 Top 3 Diaphragm Pump Innovations for Efficient Fluid Handling

In the ever-evolving landscape of fluid handling technology, diaphragm pumps remain at the forefront of innovation, continuously adapting to meet the challenges of various industries. According to industry expert Dr. Samuel Hartley, a renowned figure in the diaphragm pump sector, "The advancements we've seen in diaphragm pump technology are not just about efficiency; they are about redefining how we handle fluids across diverse applications." This statement underscores the significance of innovation in the realm of diaphragm pumps, particularly as we look toward 2025.

As we explore the top three diaphragm pump innovations anticipated for 2025, it becomes clear that efficiency, reliability, and adaptability are the driving forces behind these advancements. From enhanced materials that improve durability to intelligent control systems that streamline operations, these innovations are set to transform the way industries approach fluid handling. The future of the "3 diaphragm pump" industry promises to deliver solutions that not only meet but exceed the demands of modern applications, ensuring that businesses can operate with greater precision and reduced environmental impact. Through this lens, we can appreciate the integral role these innovations will play in shaping a more efficient future.

Revolutionizing Fluid Management: The Future of Diaphragm Pumps

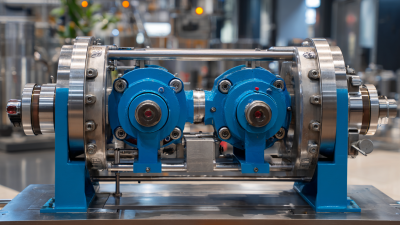

In the fast-evolving world of fluid management, diaphragm pumps are at the forefront of innovation, set to revolutionize the industry by 2025. These pumps, renowned for their ability to handle a wide range of fluids and solids, will see significant advancements that enhance their efficiency and versatility. According to a recent market analysis by Research and Markets, the global diaphragm pump market is expected to grow by 6.6% annually, reaching approximately $5.2 billion by 2025. This growth is driven by the need for effective fluid handling solutions across various sectors, including water treatment, oil and gas, and chemical processing.

The future of diaphragm pumps lies in the integration of smart technologies that improve operational efficiency. Innovations such as IoT-enabled pumps will offer real-time monitoring, predictive maintenance, and enhanced control over fluid delivery. Furthermore, advancements in materials science will lead to the development of more resilient and chemically resistant diaphragms, expanding the range of applications these pumps can serve. A study by Global Industry Analysts indicates that pumps equipped with automation features are projected to account for over 30% of the market share by 2025, emphasizing the industry's shift towards smarter, more efficient fluid handling systems. As diaphragm pumps embrace these changes, they are poised to become essential tools in creating a more sustainable and efficient fluid management ecosystem.

2025 Top 3 Diaphragm Pump Innovations for Efficient Fluid Handling

| Innovation | Description | Efficiency Improvement (%) | Key Feature |

|---|---|---|---|

| Smart Sensor Integration | Real-time monitoring and adjustments based on fluid characteristics. | 20% | Adaptive flow control |

| Extended Operating Life | Innovative materials that resist wear and corrosion. | 15% | Durable components |

| Noise Reduction Technology | Design improvements that significantly lower operational noise. | 25% | Sound-dampening materials |

Enhanced Energy Efficiency: The Role of Advanced Materials in Pump Design

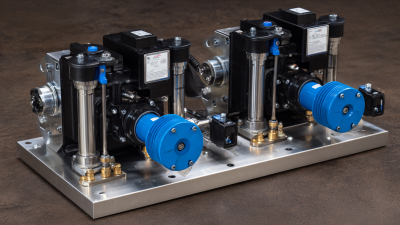

The quest for enhanced energy efficiency in diaphragm pump design is increasingly being driven by the introduction of advanced materials. Traditional materials often fall short in terms of durability and efficiency, leading to energy losses and increased operational costs.

However, innovative materials such as high-performance polymers and composite materials have emerged, offering significant improvements in both structural integrity and energy consumption. These advanced materials are not only lighter but also exhibit superior chemical resistance, allowing pumps to operate effectively in a wider range of conditions while minimizing energy expenditure.

Moreover, the implementation of smart design techniques in tandem with these advanced materials has transformed diaphragm pumps into highly efficient systems. By optimizing the shape and configuration of pump components using computational fluid dynamics, manufacturers can reduce friction and turbulence, further enhancing energy efficiency.

This synergy between advanced materials and intelligent design not only reduces the carbon footprint of fluid handling applications but also positions diaphragm pumps at the forefront of sustainable engineering practices, offering long-term benefits to industries reliant on fluid management.

Smart Technology Integration: IoT and Automation in Diaphragm Pumps

In the fluid handling industry, diaphragm pumps are witnessing significant advancements, particularly with the integration of smart technologies. The incorporation of IoT (Internet of Things) and automation in diaphragm pumps is transforming how these systems operate, making them more efficient and easier to monitor. Smart technologies enable real-time data collection, allowing users to optimize performance, reduce downtime, and lower maintenance costs. This innovative approach not only enhances operational efficiency but also aligns with broader trends towards sustainable and energy-efficient solutions.

Tips for selecting an efficient diaphragm pump include evaluating its compatibility with smart technology. Ensure that the pump you choose can integrate with IoT platforms for enhanced monitoring and control. Additionally, consider the automation features that could streamline your operations, such as remote operation and predictive maintenance alerts. By choosing a diaphragm pump that embraces these technological advancements, businesses can significantly improve their fluid handling processes.

The projected growth in the diaphragm pump market highlights the rising demand for such innovations. With market sizes expected to expand, investing in smart, automated diaphragm pumps not only positions companies for enhanced productivity but also aligns them with the future of fluid management solutions. Keep an eye on emerging technologies that can further redefine efficiency in this essential industry.

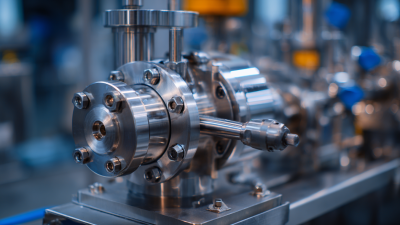

Improved Maintenance Solutions: Innovations for Longevity and Reliability

The advancements in diaphragm pump technology are making waves, especially in terms of maintenance solutions that enhance both longevity and reliability. These innovations are designed to minimize downtime and maximize performance, ensuring that fluid handling processes remain efficient. For instance, the integration of smart sensors in diaphragm pumps allows for real-time monitoring of wear and tear, making it easier to schedule maintenance before issues escalate.

Tips: When selecting a diaphragm pump, consider models with self-diagnostic capabilities. This feature can alert operators to potential problems, reducing costly downtime. Additionally, look for pumps designed with easily replaceable components, which can significantly simplify maintenance procedures.

Moreover, manufacturers are introducing materials that resist corrosion and wear, extending the life of diaphragm pumps even in demanding environments. These improvements contribute to not only lower maintenance costs but also improved overall system reliability.

Tips: Regularly check the compatibility of pump materials with the fluids being handled. Choosing the right materials can prevent premature failure and enhance pump performance. Implementing a scheduled maintenance plan is also crucial to sustaining operational efficiency and reliability.

Sustainability Focus: Eco-Friendly Practices in Pump Manufacturing and Operation

In recent years, the diaphragm pump industry has made significant strides towards sustainability, emphasizing eco-friendly practices in both manufacturing and operation. Innovative materials are being incorporated into diaphragm pumps, reducing environmental impact while improving performance. Manufacturers are exploring biodegradable and recyclable components, which not only lessen ecological footprints but also align with the growing demand for sustainable industrial solutions.

Tips for adopting eco-friendly practices include regularly maintaining equipment to ensure optimal efficiency and investing in energy-efficient designs. By doing so, businesses can minimize energy consumption and reduce overall operational costs. Furthermore, implementing regular training programs for staff on sustainable practices can foster a culture of environmental responsibility within organizations.

Another important aspect is the efficient disposal and recycling of old pumps and parts. Partnering with companies that specialize in recycling industrial equipment can help ensure that materials are processed responsibly. This not only enhances sustainability but can also comply with increasing regulatory requirements surrounding waste management in many industries.

2025 Top 3 Diaphragm Pump Innovations for Efficient Fluid Handling

This chart illustrates the impact of three key innovations in diaphragm pump technology, focusing on their contributions to efficient fluid handling and sustainability practices. The innovations include Smart Control Systems, Eco-Friendly Materials, and Energy Efficiency Technology, each measured by their respective impact index.

Related Posts

-

10 Essential Tips for Choosing the Right Air Operated Double Diaphragm Pump

-

Unlocking Efficiency: The Science Behind Performance Optimization in Electric Double Diaphragm Pumps

-

The Ultimate Guide to Choosing the Right 3 Diaphragm Pump for Your Needs

-

Why the Wilden Diaphragm Pump is the Best Choice for Reliable Fluid Transfer in Industrial Applications

-

How to Choose the Right Yamada Diaphragm Pump for Your Application in 2025

-

Why Choosing a Finish Thompson Drum Pump is Essential for Efficient Fluid Transfer

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com