Unlocking Efficiency: The Science Behind Performance Optimization in Electric Double Diaphragm Pumps

In the realm of fluid transfer technology, electric double diaphragm pumps (EDDPs) have emerged as a benchmark for efficiency and reliability. According to a recent report by Global Market Insights, the electric diaphragm pump market is projected to witness a compound annual growth rate (CAGR) of over 6% between 2021 and 2027, underscoring a significant shift towards automation and performance optimization in various industries, including chemical processing and wastewater management.

The ability of EDDPs to handle viscous liquids and abrasive substances without compromising flow rates has propelled their adoption. However, the key to maximizing the potential of these systems lies in understanding the intricate science behind their operational efficiency. By unlocking optimal performance through tailored strategies, industries can not only enhance productivity but also reduce operational costs, thereby achieving a greater return on investment.

This article delves into the critical techniques and insights geared towards optimizing the performance of electric double diaphragm pumps, setting the stage for a deeper understanding of their operational mechanics.

Understanding Electric Double Diaphragm Pumps: Key Components and Mechanisms

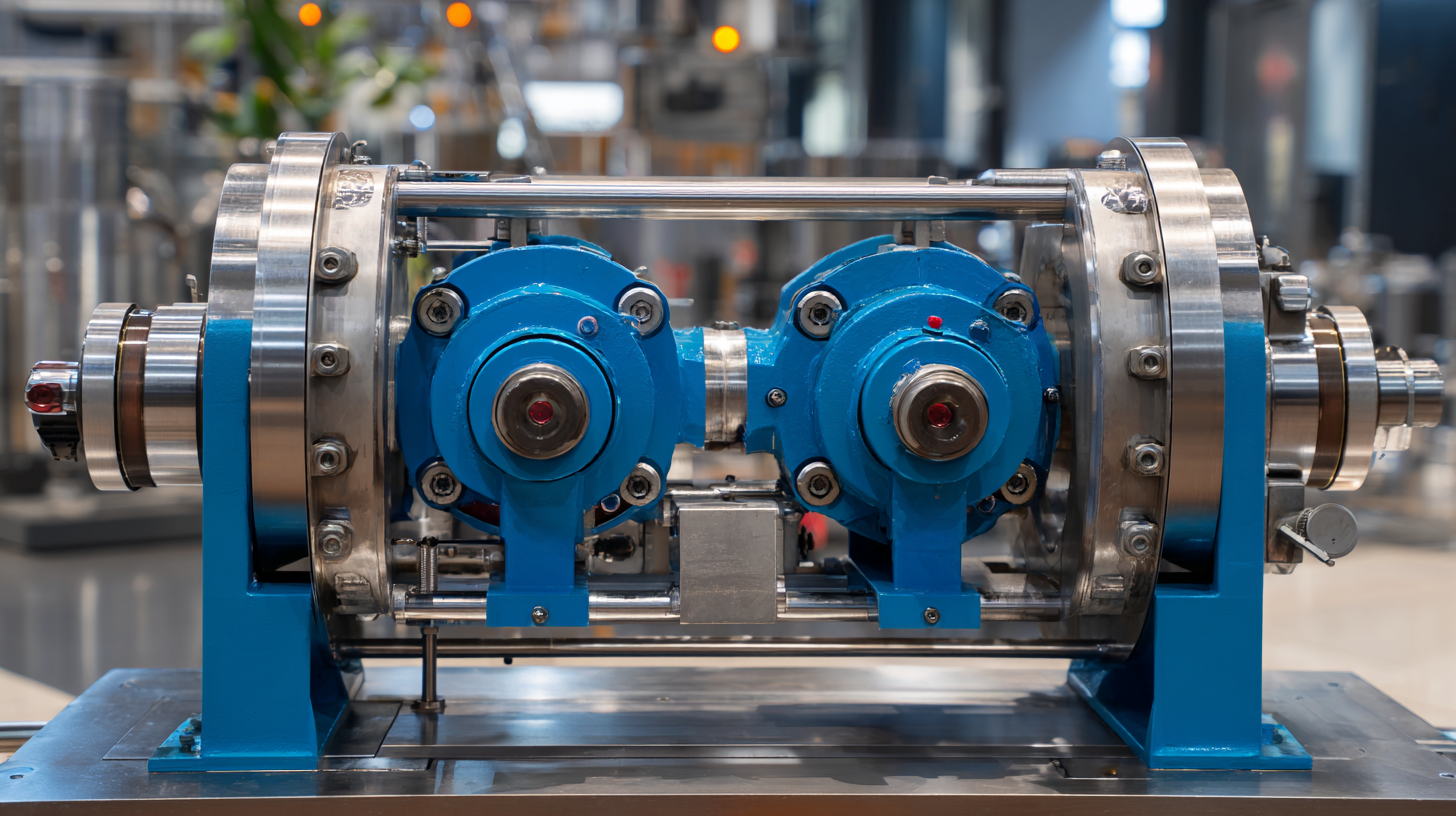

Electric double diaphragm pumps (EDDPs) are gaining traction in various industries due to their efficient, reliable performance in fluid handling. Understanding the key components and mechanisms of these pumps is crucial for optimizing their functionality. At the core of an EDDP are the two diaphragms that move in tandem, creating a pulsating action that facilitates the transfer of fluids. The use of air-driven electric motors adds to their efficiency, as they can operate with minimal energy consumption while still providing a strong pumping action.

Tips: Regular maintenance is essential for keeping EDDPs in top condition. Ensure that the diaphragms are inspected for wear and replaced as necessary to prevent leaks and maintain performance. Additionally, monitoring the air supply pressure can enhance the pump's efficiency.

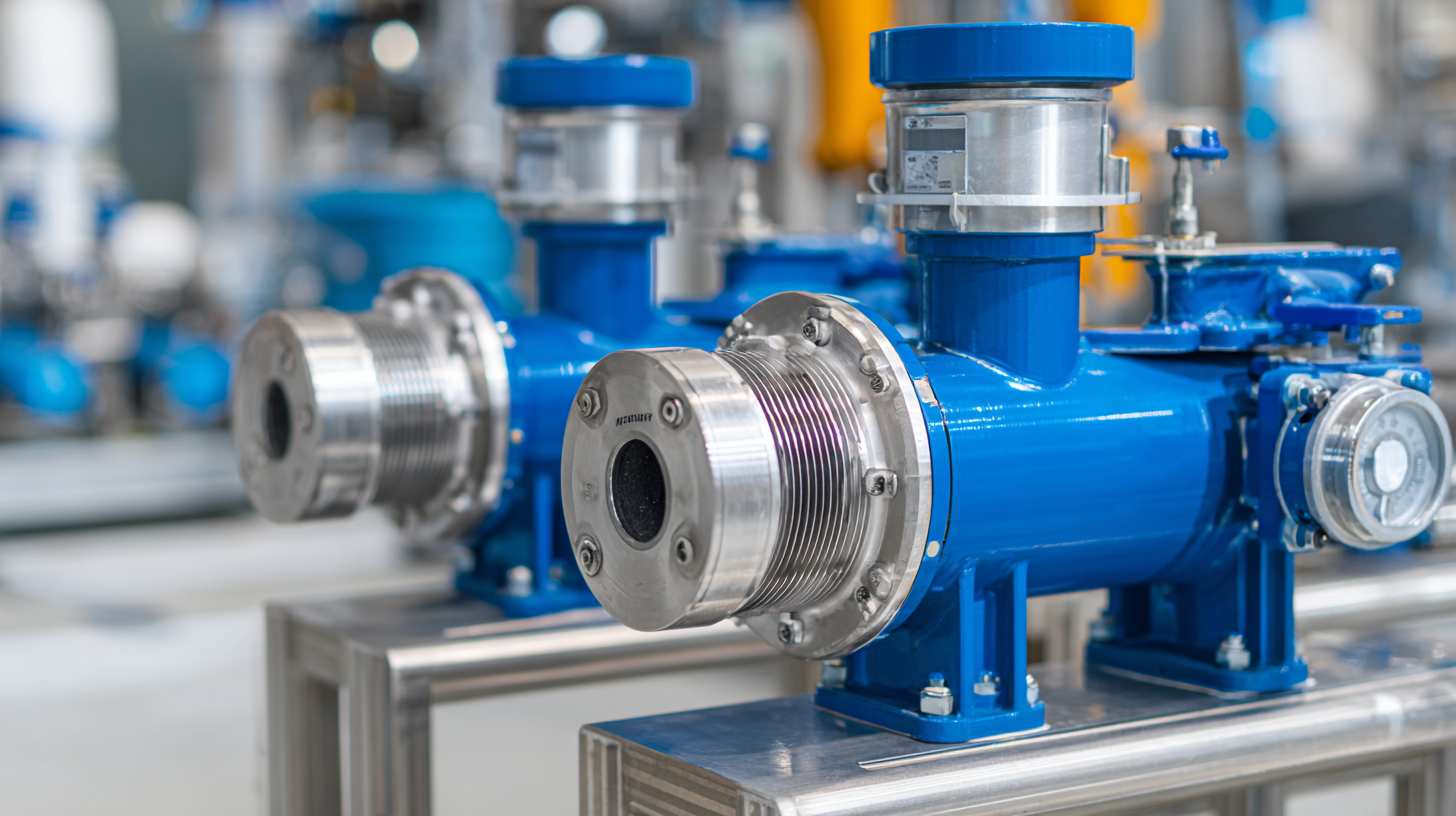

Another important aspect is the choice of materials for the pump components. Selecting materials that are compatible with the fluids being pumped can significantly impact the pump's longevity and performance. For instance, using chemically resistant diaphragms can help prevent deterioration and failure, ensuring seamless operation.

Tips: When dealing with corrosive fluids, consider using pumps specifically designed with advanced materials that resist chemical degradation. This proactive step will prolong the service life of your pump and enhance overall operational efficiency.

Unlocking Efficiency: The Science Behind Performance Optimization in Electric Double Diaphragm Pumps

| Component | Function | Material | Efficiency Impact |

|---|---|---|---|

| Diaphragm | Separates fluid from air | EPDM, PTFE | Critical for preventing leaks |

| Pump Body | Holds and directs fluid flow | Aluminum, Stainless Steel | Influences overall durability |

| Air Valve | Controls diaphragm movement | Nylon, brass | Affects pump response time |

| Check Valve | Maintains directional flow | Polypropylene, Viton | Prevents backflow, ensures efficiency |

| Actuator | Moves diaphragm | Electric Motor | Directly correlates with power efficiency |

Identifying Common Performance Challenges in Diaphragm Pumps

Electric double diaphragm pumps are widely recognized for their versatility and efficiency across various industries. However, these pumps often face several common performance challenges that can hinder operational effectiveness. According to a report from the Hydraulic Institute, nearly 30% of diaphragm pump failures are attributed to improper maintenance and wear of the diaphragm itself. This degradation can lead to reduced flow rates and increased operational costs, emphasizing the importance of regular inspection and timely replacement of components.

Moreover, the American Society of Mechanical Engineers (ASME) highlights that inconsistent fluid dynamics within the diaphragm pumps can result in cavitation, a phenomenon that damages the pump and reduces its lifespan. Data suggest that addressing such issues can improve efficiency by up to 20%, showcasing the need for effective monitoring and control systems that can detect and mitigate these challenges proactively. By identifying these common pitfalls, industries can implement targeted strategies to optimize the performance of electric double diaphragm pumps, ensuring they operate at peak efficiency.

Techniques for Improving Pump Efficiency and Reducing Energy Consumption

Electric double diaphragm pumps (EDDPs) are increasingly recognized for their efficiency in fluid handling applications. By incorporating advanced techniques for performance optimization, these pumps can significantly reduce energy consumption and operating costs. For instance, according to a 2021 report by the Hydraulic Institute, optimizing diaphragm materials and designs can enhance pump efficiency by up to 15%. These improvements allow for higher flow rates and decreased energy expenditure, ultimately benefiting manufacturers striving for sustainability.

Moreover, employing variable frequency drives (VFDs) has proven to be an effective strategy in minimizing energy consumption. With VFD technology, users can adjust pump speed to match system demand, leading to energy savings of approximately 30% compared to traditional fixed-speed systems. A case study published by the American Society of Mechanical Engineers demonstrated that EDDPs utilizing VFDs experienced reduced wear and tear, extending the lifespan of the pump while lowering maintenance costs. Implementing these optimization techniques not only boosts operational efficiency but also aligns with the industry's push towards greener technologies.

Implementing Regular Maintenance Practices for Optimal Performance

Regular maintenance practices are essential for ensuring the optimal performance of electric double diaphragm pumps. By implementing a structured maintenance schedule, operators can prevent unexpected failures and extend the lifespan of their equipment. Regular checks on pump components, such as diaphragm integrity and sealing mechanisms, not only enhance efficiency but also reduce the likelihood of costly downtime.

In addition, adopting predictive maintenance strategies can bring significant advantages. Monitoring operational data enables users to identify potential issues before they escalate, keeping the pumps functioning at peak efficiency. This approach aligns with broader industry trends, where organizations are increasingly realizing the value of diligent maintenance practices in maximizing asset performance. As seen in industries like aviation and oil, the emphasis on regular maintenance is transforming how companies manage their equipment, leading to more reliable and efficient operations.

Unlocking Efficiency: Performance Optimization in Electric Double Diaphragm Pumps

This chart illustrates the impact of regular maintenance and optimization strategies on the efficiency of electric double diaphragm pumps. Regular maintenance significantly enhances efficiency, while neglecting it leads to poor performance.

Leveraging Technology: Advanced Monitoring Solutions for Performance Optimization

Advanced monitoring solutions play a crucial role in optimizing the performance of electric double diaphragm pumps. By integrating sophisticated sensor technologies and real-time data analysis, operators can gain invaluable insights into the pump's operational parameters. These monitoring systems can track key performance indicators such as flow rate, pressure, and energy consumption, allowing for precise adjustments and proactive maintenance. The use of predictive analytics further enhances this capability, enabling users to anticipate potential issues before they escalate into costly downtime.

Advanced monitoring solutions play a crucial role in optimizing the performance of electric double diaphragm pumps. By integrating sophisticated sensor technologies and real-time data analysis, operators can gain invaluable insights into the pump's operational parameters. These monitoring systems can track key performance indicators such as flow rate, pressure, and energy consumption, allowing for precise adjustments and proactive maintenance. The use of predictive analytics further enhances this capability, enabling users to anticipate potential issues before they escalate into costly downtime.

In addition to improving efficiency, advanced monitoring solutions contribute to overall system reliability. By constantly assessing the health of the pump, these technologies can identify wear and tear or deviations from normal operating conditions. Advanced algorithms process this data, providing actionable recommendations for maintenance schedules and performance tuning. This not only maximizes the lifespan of the pumps but also minimizes operational costs. Ultimately, leveraging these technologies ensures that electric double diaphragm pumps operate at peak performance, benefiting a wide range of industrial applications.

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com