What is a Wine Transfer Pump and How Does It Work

In the ever-evolving world of viniculture, the demand for efficient and reliable tools is crucial to optimizing wine production. Among these essential tools, the wine transfer pump plays a vital role in the seamless movement of liquids throughout the winemaking process. According to industry reports, the global wine market is projected to reach approximately USD 500 billion by 2028, highlighting the need for effective equipment that can support this growing sector. The wine transfer pump not only enhances productivity but also helps maintain the quality and integrity of the wine during transfers.

With modern advancements in technology, today's wine transfer pumps are designed to cater to the specific needs of wineries, whether they are small boutique vineyards or large-scale production facilities. Research indicates that efficient pumping systems can improve operational efficiency by up to 30%, demonstrating their importance in achieving optimal results in the winemaking process. As we delve deeper into the workings of wine transfer pumps, it becomes evident that these devices are indispensable for ensuring a smooth and consistent production workflow, ultimately contributing to the success of wine businesses worldwide.

What is a Wine Transfer Pump?

A wine transfer pump is an essential tool in the winemaking process, specifically designed to move wine from one vessel to another without disturbing the sediment that can settle at the bottom of fermentation tanks or barrels. These pumps play a crucial role in various stages of winemaking, including racking, bottling, and blending. According to industry reports, the global wine production has reached approximately 246 million hectoliters in recent years, emphasizing the need for efficient equipment to manage this output.

The way a wine transfer pump works is typically through a positive displacement mechanism or a centrifugal design. Positive displacement pumps create a vacuum that draws wine into the pump and then expels it through an outlet, ensuring a gentle transfer that minimizes oxygen exposure. On the other hand, centrifugal pumps rely on a rotating impeller that creates a pressure difference, making them effective for moving larger quantities of wine. Industry professionals often prefer pumps that can handle delicate liquids, as excessive aeration during pumping can adversely affect the wine’s flavor profile.

In terms of specifications, many wine transfer pumps are designed to operate at specific flow rates, often between 5 to 100 liters per minute, depending on the size and requirements of the winery. The choice of pump can significantly influence the overall quality and stability of the final product, making it a vital piece of equipment in modern winemaking. As the wine industry continues to grow, the importance of reliable and efficient transfer systems will only increase, reflecting trends in production and consumer demand.

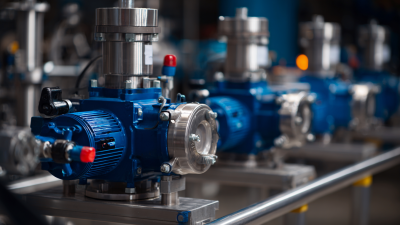

Key Components of a Wine Transfer Pump

A wine transfer pump is an essential tool in the winemaking process, facilitating the movement of wine between vessels without the need for manual handling. Understanding the key components of a wine transfer pump can help in appreciating how it efficiently operates and benefits the winemaking process.

At the core of a wine transfer pump is the motor that powers the pump. The motor creates suction, drawing the wine from one container and pushing it to another. Coupled with the motor, the pump head, typically designed for fluid movement, plays a crucial role. It is often made from materials that resist corrosion and contamination to maintain the wine's integrity during the transfer. The impeller or diaphragm within the pump head helps in propelling the liquid, allowing for a steady flow rate.

Moreover, the system contains both inlet and outlet hoses, which are vital for directing the liquid. These hoses must be made of high-quality, food-safe materials to prevent any interaction with the wine that could negatively affect its taste or quality. Additionally, a filtration system may be incorporated to ensure that any particulate matter is removed during transfer, enhancing the clarity and purity of the wine. Together, these components work in concert to ensure a smooth and efficient transfer process, crucial for preserving the characteristics of the wine.

How Does a Wine Transfer Pump Work?

A wine transfer pump is an essential tool in the winemaking process, designed to facilitate the movement of wine from one vessel to another with minimal oxygen exposure and disruption. These pumps utilize various mechanisms—such as positive displacement or centrifugal force—to ensure a gentle yet effective transfer, preserving the wine's quality and flavors. According to a recent industry report by the International Wine Association, approximately 35% of winemakers consider efficient transfer methods crucial for enhancing wine quality, directly impacting their production processes.

When a wine transfer pump operates, it typically involves the use of specific fittings that create a sealed connection between the wine source and the receiving vessel. This setup reduces the chances of oxidation, which can alter the taste profile and color of the wine. The movement can be controlled through adjustable flow rates, ensuring that delicate wines maintain their character throughout the pumping process. A study by the Wine Production Technology Group emphasizes that improper handling during transfer can lead to significant losses in aromatic compounds, making the pump's role particularly vital in preserving the wine's integrity.

Overall, the effectiveness of a wine transfer pump significantly contributes to the overall quality and consistency of the final product. As the demand for premium wines continues to rise—projected to increase by 7% annually until 2025—winemakers are increasingly investing in advanced transfer technologies to optimize their operations and secure high standards in wine production.

Benefits of Using a Wine Transfer Pump

Using a wine transfer pump offers numerous advantages for both amateur and professional winemakers. One of the primary benefits is efficiency. Traditional methods of transferring wine can be labor-intensive and time-consuming, often requiring multiple people to move wine between various containers. A wine transfer pump streamlines this process, allowing for quick and effortless transfer with minimal intervention. This not only saves time but also reduces the risk of spillage and contamination during the transfer process.

Another significant benefit is the preservation of wine quality. When using a transfer pump, the risk of oxidation is minimized because the transfer is typically done in a closed environment. This is crucial for maintaining the integrity and flavor profile of the wine. Additionally, many wine transfer pumps come equipped with gentle pumping mechanisms that prevent excessive agitation, ensuring that delicate wines are handled with care. This focus on quality retention makes wine transfer pumps an essential tool for those looking to produce exceptional wines without compromise.

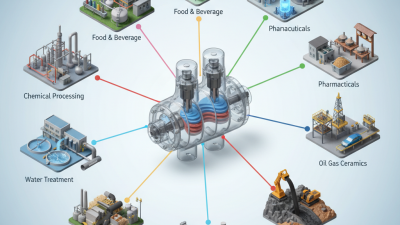

Common Applications of Wine Transfer Pumps

Wine transfer pumps play a crucial role in various applications within the winemaking process. These pumps are commonly used for transferring wine from one vessel to another, such as during racking, bottling, or tank-to-tank transfers. They help maintain the integrity of the wine by minimizing exposure to air and preventing oxidation, thus preserving the wine's flavor and quality. According to industry reports, effective wine transfer can enhance overall production efficiency, with some operations reporting time savings of up to 30%.

In addition to transferring wine, these pumps are also used for filtering and clarifying purposes. For instance, wineries may employ wine transfer pumps to move wine through filtration systems, which is essential for removing impurities and ensuring a clearer final product. Furthermore, many wineries utilize these pumps during the bottling process, where precision is paramount. A well-designed wine transfer pump can ensure consistent flow rates, which is vital for maintaining the quality of the bottling line.

Tips: When selecting a wine transfer pump, consider its material construction to ensure compatibility with your specific types of wine. Stainless steel is often recommended for its durability and resistance to corrosion. Additionally, regular maintenance and cleaning of the pump will help prevent any undesirable flavors from tainting the wine, thus enhancing the final product's quality.

Related Posts

-

2025 Top+ Drum Hand Pump: Essential Features and Market Trends in Fluid Handling Solutions

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Top 10 Best 30 Gallon Drum Pumps for Easy Liquid Transfer in 2023

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

Top 10 Diaphragm Pump Applications for Efficient Fluid Transfer

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com